Article

How do different types of IsoPlane Strain elements perform in FEA?

Back to listWindas Workstation is a specialized finite element analysis software capable of running all types of common FEA elements including both linear and higher order elements.

As of today, there are 20 FEA element types known to Windas Workstation. These include various types of 1D line elements, 2D plate / shell elements, and 3D solid elements. In this article, we will have a closer look on the basic 2D Finite Element types. These elements are known as plane strain or plane stress elements.

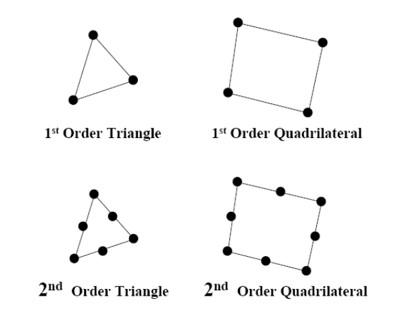

In general, we can model 2D FEA elements using triangular or quadrangular meshes. Both shapes may be defined as their 1st order and 2nd order form.

We will get acquainted to the 5 types of elements below:

- 1st order triangle, also known as TRI3 elements, are the basic 3 nodes triangles. This element is presumed to perform the worst in terms of finite element analysis due to the stiff nature of the triangle shape. The 3 nodes triangle requires deformation to be in a “perfect plane” and therefore is lacking linear interpolation.

- 2nd order triangle, known as TRI6, are 6 nodes triangles with intermediate nodes in between the vertex nodes. Due to the interpolated node, this element is expected to perform better than the lower order. The mid nodes allow the element to capture the bending effect on the element.

- 1st order quadrilateral, also know as QUAD4 elements, are the basic 4 nodes quad. This element type is the most generic in finite element 2D analysis.

- 2nd order quadrilateral, known as QUAD8 elements, are 8 nodes quads with intermediate nodes in between the vertex nodes.

- Hybrid element on QUAD4. Hybrid elements may look the same as QUAD4, but the analysis formula is completely different. Evidently, it produces much more realistic results compared to the former.

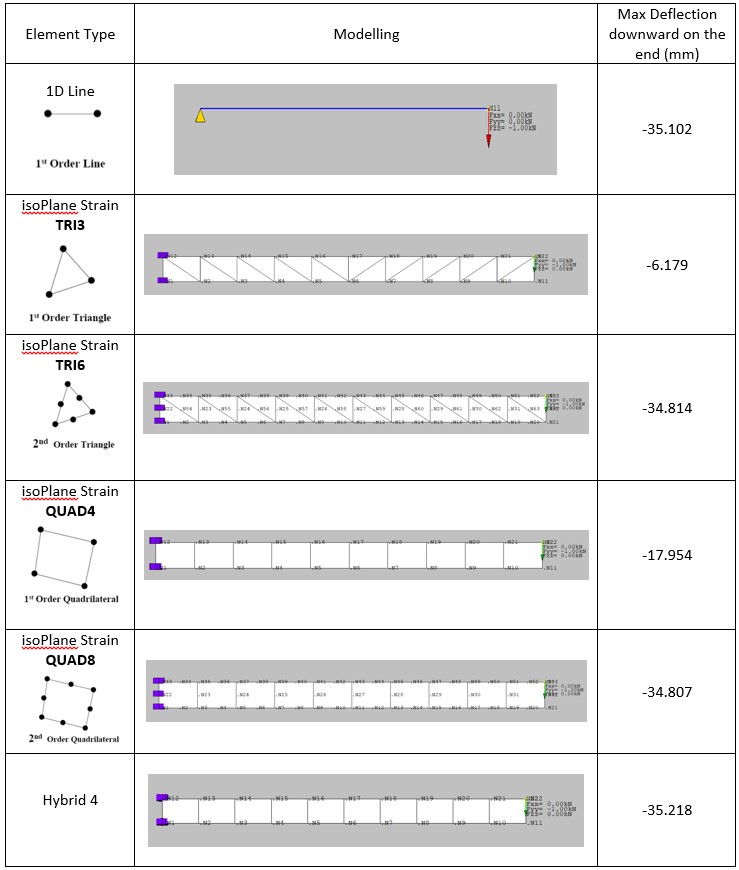

For each type of the above elements, we will run a test case analysis where the boundary conditions are exactly the same and observe the results.

The test case will be a generic cantilever beam of 15m. It is fixed on one end and a gravity point load of 1 kN is applied on the other end. The assigned material is a mild steel (E = 205000 Mpa) solid section of 1000mm depth and 10mm thickness.

A traditional Bernoulli beam analysis on a line element assigned as beam 3D is set as a sample case. The result from this analysis shall be the reference.

The results summary is as follows:

As predicted, the higher degree elements produce more realistic result compared to the 1st order elements. Albeit represented in 1st order quad, the Hybrid 4 shows rather realistic results as well.

The analysis using TRI3 and QUAD4 elements can be improved by further discretization. However, having more elements will consequently require more memory and time to run the solver.

All in all, it is important to utilize an FEM software that supports various type of elements to be analyzed for better confidence in the results. With Windas Workstation as our in-house software, our team is able to analyse a diverse range of Tensile Membrane, ETFE Skylight, Spaceframes and Greenhouse structures, giving us more design freedom.